I have almost all variations of standard replaceable soldering iron tips in my arsenal, from conical and chisel types to bevel tips. In theory, each tip is supposed to be used for its specific purpose, however in practice the most common ones that I constantly use are conical and chisel tips. I’m not saying that you should do the same, it’s just a matter of habit and practice.

And doesn’t matter what types of tips you use, they all get oxidized dirty after any soldering and need to be cleaned and taken care of. And here I’m going to share my ways and tips of keeping the tools in a proper and working condition.

Attention:

- Never ever clean it with the sand paper! Doing so you are going to take all the coating off and your tip would be nothing but a piece of core metal, that is going to oxidize and eat itself. Just remember that a sand paper is the best way to destroy any soldering tip.

- In case of an oxidized tip never increase the temperature of your soldering station: it will make your problem a lot worse. When you get an oxidized tip, you need to turn the station off, wait till the tip gets cold and clean it with a polishing bar. (read below)

I’m going to tell you how to clean and maintain a soldering iron tip to ensure its longer life. Just to let you know: all my soldering tips look like new and I use them on a daily basis. The only reason for this is that I clean them after each use.

Cleaning a soldering tip: different techniques

1) Polishing bar

If your soldering tip gets slightly oxidize, switch off the soldering station and wait till the tip becomes cool. Then take the polishing bar and start rubbing the tip on the polishing bar. That will rub off an oxidation, and it won’t remove the coating in the soldering tip. However, you should be very gentle: there’s no need to push very hard to get the oxidation off.

Remember:

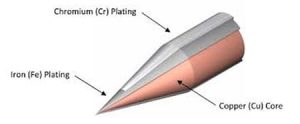

The soldering tip has a copper core and an iron plating at the end of the working area.

2) Soldering tip tinner/cleaner

Note: A tip tinner is a mild acid, helping to remove baked on residue or prevent oxidation accumulating on your soldering tip. A handy thing to have in your arsenal of soldering accessories.

In the more severe cases soldering tip tinner would do the cleaning better than a polishing bar. You are supposed to use soldering tip tinner when the soldering tip is hot. The only thing you need to do is to simply dip it in there, move it around and this stuff will eat the oxidation in the tip.

3) Soldering tip brush cleaner

One of the best cleaning methods is with a brush. Take your brush and clean the soldering tip. After that you can finish cleaning with the polishing bar.

Remember: Oxidation doesn’t transfer temperature. When a tip is oxidized, it won’t transfer the heat properly.

4) Soldering tip Cleaning Sponge

Don’t mix this special sponge for soldering with any other types of sponges, kitchen sponge, for instance. This sponge is a high-temperature sponge and it is designed to the work with very hot soldering tips. Any home sponge has contaminants inside. And when you wipe the tip, all the dirt will be transferred to it.

A sponge should be cleaned. There’s no sense to clean a soldering tip on a dirty sponge.

Tip:

In order to have a soldering tip in a good and working condition, you need to wipe it off either with a sponge or a cleaner at least in between of your work, if not after each use.

5) Tip Dry cleaning system

This system contains metal wool sponge and is designed for soldering tip cleaning. If you use water soluble flux, this system prolongs wettability of the soldering tip. However, lots of modern soldering systems have this dry clean in-built.

6) Soldering wire

Soldering wire is designed to help soldering tips last longer. You need to heat the soldering iron, dip it into the flux, and then touch the wire getting a decent amount of solder on it and wipe the tip off. Your soldering tip is clean! If you were not able to clean the tip thoroughly after the first time, repeat it again.

How to get maximum of your soldering tip life?

Just keep it in mind. Doesn’t matter what tip you use: a chisel or a round one (conical style). A chisel tip has two sides and a conical has 360˚. So, when you are soldering, you shift the tip around. Don’t over solder on one side only. Because very soon the iron gets compromised, as copper dissolves on one side only. And clean it, of course.

Conclusion

If you want to maintain a soldering tip life for a long time, keep it clean and do the cleaning using the methods stated above. Hope, these techniques will save your time and time, and you will have a good quality and ready-to-use tools.